How to Determine Which Aluminum Welding Wire to Use

5356 is one of the most used types of wires due to its versatile usage. Assemble your wire welder using a wire tip larger than the wire size you will be using.

Flux Core Aluminum Welding Wire What You Need To Know Welditu

You can do this by using a firemans weight to force the metals through a tube which is then melted down into the gunmetal shape.

. Choosing the right wire diameter for welding. One of the good products to use when welding aluminum is the HARRIS 05356F1 MIG welding aluminum wire. If this was a job to be done with stick electrode we would need to use an efficiency of 65 much lower due to stub loss slag and spatter.

It may also be used to weld 3xxx series alloys or 2xxx alloys. Just imagine trying to feed a hollowed-out flux core wire without crushing and jamming. ER4043 GTAWGMAW ER4043 is silicon alloyed 5 aluminum TIG wire used for welding of 6061 grade.

Use multiple pass straight beads to improve the overall appearance of the weld and help to avoid defects. Based on the thickness of your base metal you will determine the thickness of the welding wires used. 5 The aluminum series 5000 that makes up the electrode wire.

These are commonly referred to as welding consumables since they burn up during use. Match your rod filler to your welding wire. Even solid aluminum wire is soft and tricky to feed.

One of the decisions a welder must make when working on thin sheets is the type of welding wire. Avoid pulling while weldinginstead push at a 10 degree to 15 degree angle. GMAW requires a solid wire electrode or a composite metal-cored electrode.

4043 can also be used for welding castings. A family of high-strength sheet and plate alloys. Multi-pass welding or a beveled joint design may be required on material thickness 316 and greater depending.

If you select wire that is too small for the material the welding process is inefficient costing time and production as the welder has to spend more time completing the weld. These are typically used as welding or brazing filler alloys rather than base materials. 4043 is designed for welding 6xxx series aluminum alloys.

The most common types of MIG wire for welding mild steel are ER70S-3 and ER70S-6. With MIG the constant heat output can be sustained until the aluminum pieces have been well fabricated. It is an all-position non-heat-treatable MIG wire suitable for 5000 series aluminum base metal but without 40 000 psi tensile strength is a requirement.

If your welder has a steel wire liner remove it and replace it with a plastic or Teflon liner so that the aluminum wire wont bind up. This is best calculated by using deposition rate. Its produced from a state-of-the-art facility entirely built around aluminum wire production with custom-built equipment and proprietary.

ER5356 is a popular choice of MIG wire for welding aluminum grade 5050 5052 5056 5083 5086 5155 5356 5456. Carbon steel stainless steel and aluminum. Recess the contact tip of your welder approximately 18-inch inside the nozzle of the welding tip.

We have different types of aluminum welding wire for sale we have different types of stainless steel welding wire listed in each page for example our aluminum welding wire is of good plasticity S301 and ER1100 welding wire is suitable for gas shielded or submerged arc welding for corrosion resistant aluminum S5356 and ER5356 aluminum welding wire is of good. We divide the total weld metal needed by the efficiency 5216095 and this gives us the amount of weld wire that needs to be purchase which in this case is 5491 pounds. TIG MIG Filler wire for 6061-T6 Welding.

Hot-rolled aluminium Welding is a process that requires metal to metal contact and communication. Youll want these to be the same size as your TIG welding electrodes. These base metals as they are called influence the composition and thickness required of the welding wire.

It is also the best choice for avoiding silicon. This calculation is for steel only. Aluminum wire is supported and manufactured by a team with decades of expertise in aluminum filler metals.

It can also cause quality control issues as the welds. For best results welding professionals go for a wire or rod similar to the aluminum pieces they are working on. Browse discover thousands of brands.

From left to right the name means. The mechanical properties and strength of the weld deposit depend first on the chemistry of the wire and second on the type of shielding gas used see Figure 1. Read customer reviews find best sellers.

However if you are going to be working on very thin steel such as automotive sheet metal you may want to go thinner and use a wire that is 024. Even though various metals can be used in MIG welding the three most common are. The wire offers very good weld fluidity with a good weld appearance.

Torch Welding is not as widely used as TIG or MIG. ER 4043 or ER 5356 is ideal for most jobs. Deposition Rate lbhr 131 x wire diameter 2 x wire feed speed x efficiency Wire diameter in inches in Wire feed speed in inches per minute inmin Efficiency 10 for solid wire 085 for cored wire.

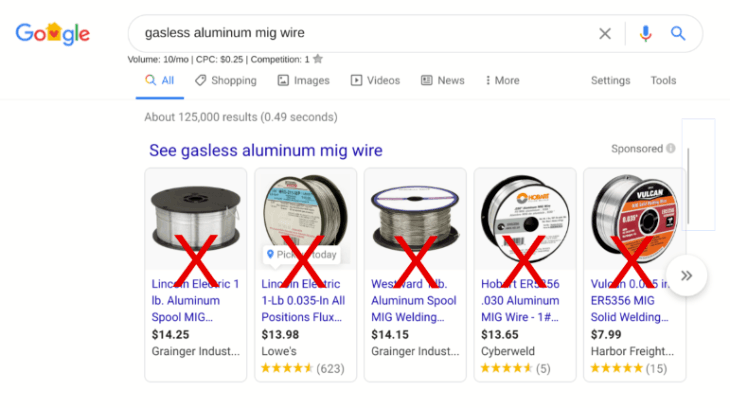

These wires are designed to meet minimum tensile strength requirements of 70000 psi. 5000 series aluminum alloys are readily welded with 5356 filler metal. Why No Flux Core Aluminum Welding Wire.

LONGEVITY is recognized worldwide for providing reliable Welding cutting and power generating equipment. Several problems prevent the use of FCAW aluminum wire. However when they are used as base materials 4000 series aluminum alloys are readily welded with 4043 filler metal.

4 Tips To Help Choose Welding Wire. 4043 has a lower melting point and more fluidity than the 5xxx series filler alloys and is preferred by most welders because it wets and flows better and its less sensitive to weld cracking with the 6xxx series base alloys. The wire packaging will include a chart to analyze the wire thickness for the metal you use.

Recommended Welding Wire Size Chart. Basic wire drives just wouldnt be up to the task. If you are going to be welding on thin metals a wire size of 030 will be sufficient.

The two most common types of aluminium welding are cold-rolled Aluminum and hot-rollable Aluminum. The primary consideration in choosing welding wire diameter is the thickness of the material being welded. But which one is best for a particular application.

Argon gas is used as a shield during the welding process. Ideally the welding wire will be the same type of. Since our start 2001 LONGEVITY has earned our slogan The Power to Last through innovation customer satisfaction and industry leading production.

Aluminum grade 6061-T6 is welded using ER5356 ER4043 and both filler wires can be used to weld Aluminum 6061 grade. Clean your aluminum remove any oxide and file the edges that will be joined. 356 Indicates the amount of magnesium added to the electrode.

Quality Aluminum Weld Wire. Solid wire electrodes commonly are referred to as GMAW electrodes. Prepare your push-pull wire feed.

ER70S-3 is typically used on clean oil-free and rust-free base material. These include usability and quality issues. The smallest size flux-core welding wire is 030.

As a premium filler metal solution Hobart.

0 035 In Er5356 Mig Solid Welding Wire 1 00 Lb Roll

Getting To Know Flux Cored Wires

Flux Core Aluminum Welding Wire What You Need To Know Welditu

No comments for "How to Determine Which Aluminum Welding Wire to Use"

Post a Comment